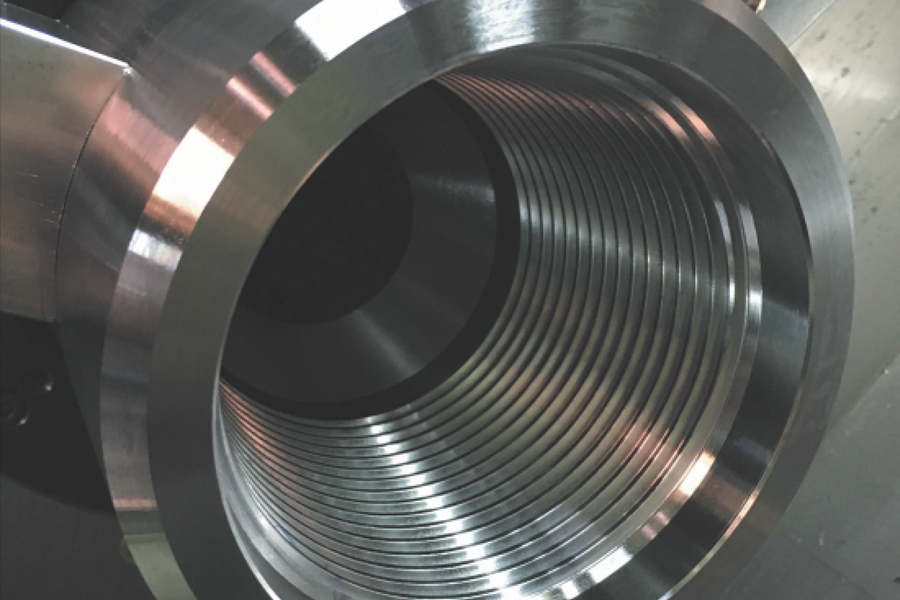

In the world of precision engineering, where every micron counts, the importance of accuracy cannot be overstated. Top-grade custom machining solutions thrive on a foundation where accuracy is never compromised. Whether it is aerospace components, medical devices, automotive parts, or intricate industrial machinery, the demand for flawless precision drives every step of the machining process. Custom machining is not merely about shaping metal or other materials; it is a highly technical craft that integrates advanced technology, skilled craftsmanship, and rigorous quality control to deliver parts that meet exact specifications consistently. Precision machining specialists understand that even the smallest deviation can result in failures, reduced performance, or costly rework, which is why accuracy remains the cornerstone of their service promise. From the initial design phase to the final inspection, maintaining tight tolerances is critical. Modern custom machining companies invest heavily in state-of-the-art CNC Computer Numerical Control machines, 3D modeling software, and automated measuring instruments to guarantee that each piece adheres to the specified dimensions and finishes.

CNC machines enable unparalleled precision by automating complex cuts and repetitive processes, reducing human error and enhancing consistency. Beyond machines, the expertise of seasoned machinists plays a crucial role they interpret blueprints, adjust tool paths, and make real-time decisions to ensure that the end product aligns perfectly with design intent. This blend of technology and human skill ensures that accuracy is embedded throughout the manufacturing process. Moreover, top-grade custom machining firms implement stringent quality assurance protocols. Parts are subjected to multiple inspections using tools like coordinate measuring machines CMMs, optical comparators, and laser scanners to verify that every angle, hole, and surface meets the rigorous standards demanded by clients. This online cnc service multi-level inspection system allows companies to catch any discrepancies early, preventing flawed parts from advancing down the production line. Consistent documentation and traceability also play a vital role in assuring clients that their components meet regulatory and industry standards, further cementing trust in the machining provider’s commitment to precision.

The significance of accuracy extends beyond product quality it also affects cost efficiency and project timelines. By maintaining exacting standards, custom machining companies minimize material waste, reduce the need for costly adjustments, and avoid delays caused by rework or rejected parts. This efficiency translates into faster turnaround times and competitive pricing, which are essential factors in today’s fast-paced manufacturing environments. Additionally, the ability to reliably produce highly accurate parts opens doors for collaboration across sectors that demand innovation and excellence, including robotics, electronics, and defense industries. In conclusion, accuracy is the lifeblood of top-grade custom machining solutions. It is the principle that governs every machine setting, every operator’s move, and every quality check. The dedication to precision is what differentiates the best machining providers from the rest, enabling them to deliver superior, reliable, and perfectly tailored components that meet the exact needs of their customers. When accuracy is never compromised, it sets a standard of excellence that drives innovation and success in manufacturing worldwide.